Corrosion Technologies

- Home

- Corrosion Technologies

Corrosion Technologies

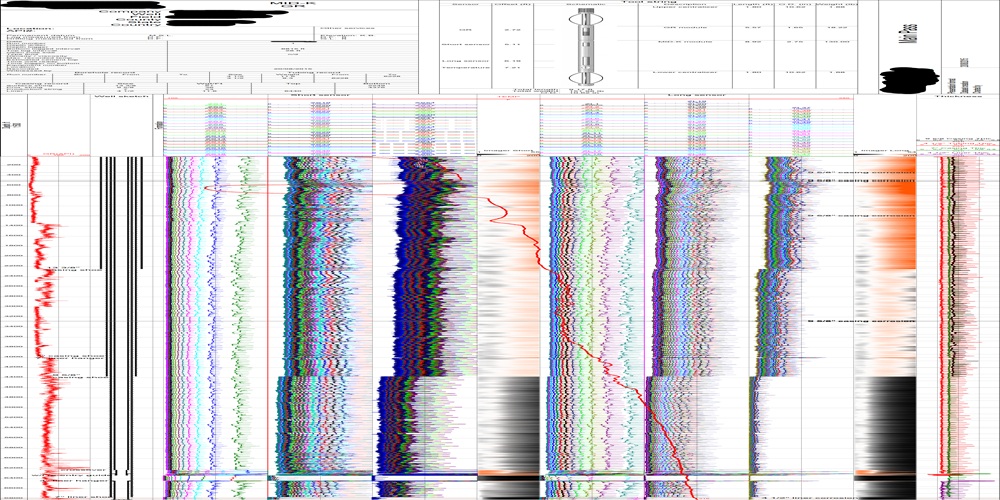

Magnet Impulse Detector

Magnetic-pulse defectoscope technology has no analogues in the world.

Work has been carried out on more than 2000 wells in the Middle East. A special feature of the method is the ability to study the technical condition in a multi-column structure, through the tubing with the definition of violations and thicknesses of the

2nd, 3rd and 4th production well casing. The technology allows:

-to determine the location of through violations;

-to determine the rupture of pipe in a two- well casing structure;

-to determine the actual intervals for installing sealing patches;

-to determine the actual depth of installing casing packers, etc.;

-to clarify the well design if there are up to four well casing;

-to check the compliance of the installation intervals of well casing sections with the design with different internal diameters and wall thicknesses;

-to determine the actual intervals for installing sealing patches;

-to determine the actual depth of installing casing packers, etc.;

-to determine the intervals of corrosion and the degree of wear of the well casing;

-to determine the intervals of column violations requiring repair;

-determine the thickness of the first tubing, second and third production well casing.

-Error in determining the pipe wall thickness, mm: – for a single-casing – 0.5mm., when measuring the production casing through the tubing – 0.7mm.